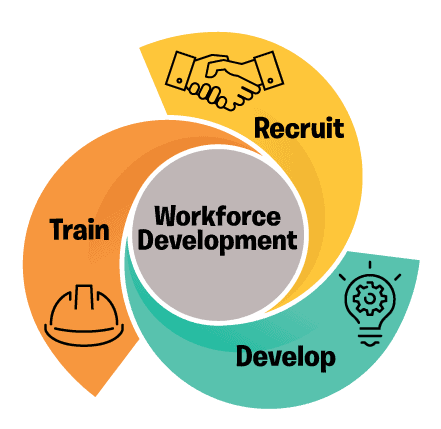

Recruit, Train, Develop. Repeat.

“Workforce development encompasses four key areas—recruitment, assessment, training, and leadership management. Organizations that only focus on one or some of these areas will never fully solve their skilled workforce challenges,” said Pete Krammer, Senior Partner of Okos Partners.

Crane Industry Services (CIS) uses cutting edge training and assessment tools to help employers achieve organizational excellence. “Self-sustaining workforce development—not just mere compliance—is at the heart of what CIS offers construction, utility, manufacturing, and heavy industry markets,” said Debbie Dickinson, CEO of CIS.

The company’s workforce development consulting services incorporates the TradeUp program, which is a collaboration with Okos Partners.

The following interview provides additional insight into the forces that impact the complex issues of workforce development.

Are you seeing trends among employers regarding the realization that they need comprehensive workforce development plans? If so, what has shifted that focus from the over-simplified idea that there just aren’t enough people coming into the trades?

Dickinson: An operations manager for a national stevedoring employer recently told us: “Our company has enough opportunities to double its business. However, the key to being able to grow is in recruiting, training, and having qualified skilled labor, ready to work.” Businesses are realizing their growth and profits are hindered by not having enough people with the right skills.

The manager went on to say that they are actively setting up programs to train people who want to work. Employers are realizing that they can’t simply recruit a ready-made employee. They must provide their own training to develop people who do not currently have skills but want to learn and work. Doing so is critical to sustaining and growing. Thinking that someone else will train and develop is an opportunity killer.

Historically, one of the fears of employers is that if they spend money on training, employees will leave to go work for a competitor for minor hourly increases. That’s outdated thinking. Studies show that people more often leave because they don’t trust management or there are not clearly identified career growth opportunities. Developing people helps solve both of those problems. We all need to work together to provide opportunities and career enhancements to people who are willing to perform work that is financially and personally rewarding.

Krammer: Employers have recognized that they must approach workforce development differently than they have in the past. And, slowly, they are beginning to understand that the challenge is not just finding people, it’s keeping them. Creating an environment for workers to grow and thrive in is the leadership challenge that faces every manager, from the foreman to the CEO. There is a trend in industries that rely heavily on skilled labor to build a level of trust integral to encouraging employees to commit and motivate themselves. That requires a set of conditions where employees feel that they can safely engage with management, whether it’s providing input to work planning and processes, or making decisions. If individuals are connected to the goals of the project and the company, and to each other, then they feel valued, like they are contributing, and are more inclined to stay. A management culture that cannot build and maintain these conditions will face increasingly difficult challenges finding and maintaining the crews and teams that help their business grow.

Often workforce development is only defined as recruiting. But it is so much more than that. Do you think internal development of employees is more or less important than recruiting new employees? Why or why not?

Krammer: This is exactly the principle behind TradeUp, a process that helps employers with recruitment, assessment, training, and leadership management. Everyone is naturally motivated by opportunities to advance. Some people are driven by doing the work well and continually improving. Others are driven by results, and the better the result, the more motivated they become. Others need additional responsibility and want to lead. Understanding what drives the people you recruit, and providing a path that fits their individual goals and motives creates a lot of positives: better retention, higher quality, higher efficiency, lower costs, greater profits. This allows a company to recruit more strategically with the knowledge that those they bring in will prosper and help the company grow while they grow themselves. This is the heart of workforce development.

Dickinson: Workforce development has to happen both internally—often called reskilling or upskilling—and externally—which falls into the recruiting category. A successful program must provide training to address the needs of individuals in three skills levels: Novice, Intermediate, and Journeyman craft professionals. We like to call this Recruit, Train, Develop, Repeat.

So, yes, if your workforce development only focuses on recruiting you are taking one step forward and two steps back. The full package should include career paths for people at all levels with accompanying pay scales, benefits, and most importantly, opportunities, based on business goals and the achievements of individuals.

How can HR, Safety, Project Management, and other departments work together to make this Recruit, Train, Develop, Repeat concept successful?

Dickinson: Workforce development is an all-company strategy. HR and Project Management may be key drivers but every craft supervisor and employee need to know their leaders are knowledgeable, accessible. Leaders must also be advocates for craft professionals.

Project management should review work plans frequently to know what has changed and what different skill sets may be needed. Likewise, assessing skills and qualifying individuals for work is integral to a strong safety culture. In return, a reputation as a safe company by itself becomes a recruiting tool that HR can use.

We work with all of these departments to make sure they are in sync when it comes to workforce development.

Krammer: A formal plan is critical to the Recruit, Train, Develop, Repeat process. The planning needs to involve Senior Management, HR, Safety, Project Management and other departments. The success of this workforce development plan depends on alignment with these different perspectives. This approach sets the foundation for a companywide culture of commitment and engagement, with everyone involved.

Furthermore, this concept applies to both Union and Open Shop work. Unions heavily rely on the recruiting and training piece, however, management needs to also be aligned with those activities by providing career growth opportunities. In Open Shop environments, leaders must manage the spectrum of Recruit, Train, Develop, and Repeat processes.

What tools or tips do you recommend to help employers establish this mentality for their workforce development?

Dickinson: Employees often are the ones closest to the problems. They see where time or money is wasted. I suggest starting daily task and safety briefings with open ended questions. Listen. Recognize crews and individuals who do a good job. For example: Does anyone have a suggestion for how to rig this load in a safer way? What gear or equipment would make the job easier? Based on the plan, what recommendations do you have to make the work safer and easier? FYI, safety and better practices go hand-in-hand and yield higher productivity.

Demonstrate leader accountability and awareness of what takes place on job sites. If workers can anticipate leaders coming to them to ask what they are doing and the best way to get the job done, that gives employees opportunities to shine. Recently, CIS was on a jobsite helping an employer develop a safety plan. Cliff Dickinson, CIS President, noticed a pile of steel that was not stacked correctly. If someone stepped on a bottom piece, the pile could have toppled. He put on gloves, gathered a few people he was there to train, and in minutes they straightened the pile. He told the crew, “If we walk by and see a potential problem, we are the best ones to fix it, right then and there.” The crew agreed and was glad to be a part of the solution. The work took minutes and prevented a possible injury.

Lance Simons, VP of Safety and Quality, for the Haskell Co. Inc., a full-service engineering and construction firm, stands firmly against the idea that “Safety” is a department that operates independently from the rest of the business. He insists that safety is a part of every task, project, and plan. We wholly agree. Too often safety is considered the Safety Manager’s job or safety is incorrectly viewed only in the context of compliance requirements. Core to safe work are people who are trained and skilled to perform optimally, which a compliance checkmark alone will never reach.

In addition, one reason that the future workforce is cautious about choosing a career in skilled trades is the horror stories of injuries. A well-trained, continuously skill-developed workforce, with career advancing opportunities are keys to success.

Krammer: Safety culture means that the work is done, and the teams are led safely. Period. Culture is driven both from the top down and from the bottom up. It requires a concentration on both day-to-day operations and long-term planning. We employ a Vital Statistics Report that analyzes how in sync workers and leaders are. When crews are in sync, productivity and safety results can soar.

How can employers measure if they are being successful?

Krammer: Too often data is merely a reflection in the rearview mirror. Did we hit the timeline? Did we hit the budget? Did we stay safe? However, while we’re collecting job data and before we can report on it, work is being done, and it’s difficult in the heat of the action to know how it’s being done unless you ask the people who are doing it.

At periodic intervals we survey people’s perceptions of their immediate crew’s effectiveness along six dimensions: communication, accountability, feedback, structure (process effectiveness), cohesion, and emotional intelligence. These are correlated to labor costs so that people understand that whether you excel or have challenges in any of these areas, there are hard costs associated with these “soft skill” behaviors. Positive movement means positive financial results, for sure, but more importantly, these six areas of team and crew performance are the key drivers of creating conditions of motivation and commitment. By measuring these factors, employers gain deep insight into the culture and conditions of their crews and can take prescriptive actions while the work is being done so that how the work is being done can continually improve.